RM 2RH Isikhululo esiphindwe kabini se-IMC somatshini wokuThermoforming

Iiparamitha zoomatshini

| ◆Imodeli: | I-RM-2R |

| ◆Max.Ingingqi yoLwakhiwo: | 820*620mm |

| ◆Max.Ukubumba ubude: | 80mm |

| ◆Ubukhulu.Ukutyeba kweShiti(mm): | 2mm |

| ◆Uxinzelelo loMoya oluPhezulu(Ibha): | 8 |

| ◆Isantya soMjikelo owomileyo: | 48/cyl |

| ◆ Amandla okuqhwaba: | 65T |

| ◆Isixhobo sombane: | 380V |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Isinciphisi: | GNORD |

| ◆Isicelo: | iitreyi, izitya, iibhokisi, izivalo, njl. |

| ◆ Amacandelo angundoqo: | I-PLC, i-injini, i-Bearing, i-Gearbox, i-Motor, i-Gear, i-Pump |

| ◆Izinto ezifanelekileyo: | PP.PS.PET.CPET.OPS.PLA |

| Max. Ukungunda Imilinganiselo | Amandla okuQhwatha | Isantya soMjikelo owomileyo | Max. Iphepha Ukutyeba | Max.Foming Ubude | Max.Umoya Uxinzelelo | Umbandela Ofanelekileyo |

| 820x620mm | 85T | 48/umjikelo | 2.8mm | 180mm | 8 Ibha | PP, PS, PET, CPET, OPS, PLA |

Ividiyo yeMveliso

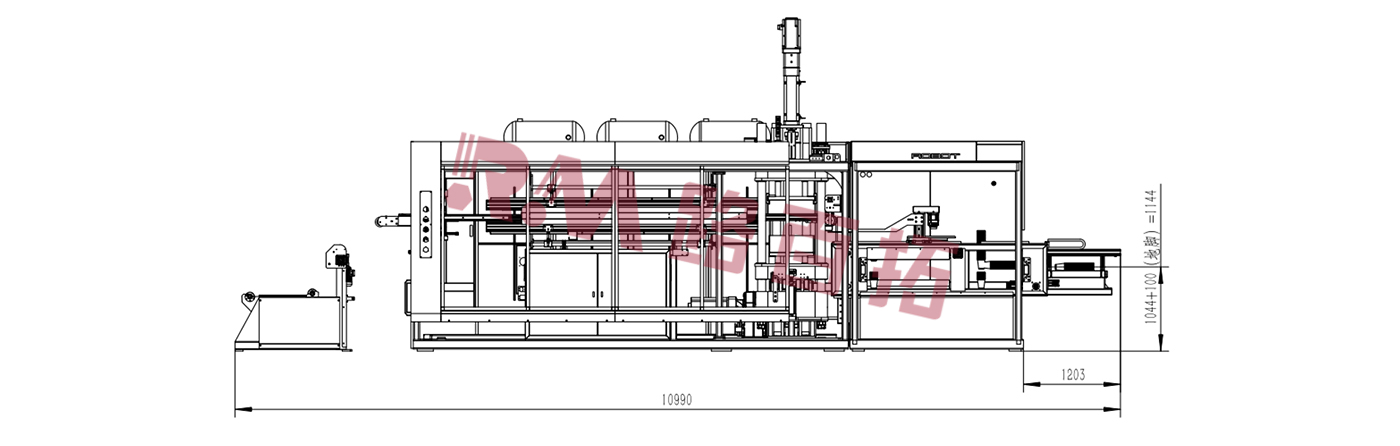

Umzobo wokuSebenza

Iimpawu eziphambili

✦ Fumana inqanaba elitsha lemveliso kunye noMatshini wethu woBume be-Automatic High-Speed and Cutting Machine. Ibandakanya uyilo lwezikhululo ezibini, yenza ukubunjwa kunye nokusika ngaxeshanye, inyusa kakhulu ukusebenza kakuhle kwemveliso. Inkqubo yokusika i-in-die iqinisekisa ukusika ngokukhawuleza kunye nokuchanekileyo, okwenza inkqubo yokuvelisa isebenze ngakumbi.

✦Imodeli yethu inika amandla okwenza uxinzelelo kunye nokungalunganga. Ngokusebenzisa ukushisa kunye noxinzelelo, iphepha leplastiki liguqulwa libe yimo yemveliso efunwayo. Ukwenziwa koxinzelelo olufanelekileyo kuqinisekisa umgangatho wemveliso ogudileyo kwaye ungaguquguqukiyo, ngelixa ukubunjwa koxinzelelo olubi kuqinisekisa ukuchaneka kweempawu ze-concave kunye ne-convex, okukhokelela ekuzinzeni kunye nomgangatho ophezulu wemveliso.

✦Uxhotyiswe ngenkqubo yokuphalisa kwi-intanethi, umatshini wethu ufezekisa ukupakishwa okuzenzekelayo kweemveliso ezigqityiweyo. Le nkqubo yokupakishwa elungelelanisiweyo yonyusa kakhulu impumelelo yemveliso kwaye inciphisa ukuqina kwabasebenzi, ivumela iqela lakho ukuba ligxile kweminye imisebenzi ebalulekileyo.

✦Umatshini wethu ulungele ukuvelisa iimveliso ezinobude obuncinci njengekomityi yesosi elahlayo, iipleyiti kunye neziciko. Nangona kunjalo, iyakwazi ukuziqhelanisa ngokulula nobukhulu obuhlukeneyo bemveliso kunye neemilo. Ngokutshintsha nje ukubumba kunye nokulungelelanisa iiparamitha, uluhlu olubanzi lweemveliso lunokwenziwa.

✦Tyala ngokusebenzayo kunye nomgangatho ngoMatshini wethu oSebenzayo oSebenzayo ngesantya esiphezulu kunye nokusika. Ukubunjwa kunye nokusika ngaxeshanye, amandla afanelekileyo kunye noxinzelelo olubi, ukupakisha okuzenzekelayo, kunye nokuguquguquka kwimveliso yemveliso - konke kwisisombululo esinye esinamandla. Hlala uphambi kokhuphiswano kwaye uphakamise amandla akho okwenza ngomatshini wethu wokusika!

Indawo yesicelo

Lo matshini we-2-station thermoforming usetyenziswa kakhulu ekupakisheni ukutya kunye namashishini okutya. Ngeengenelo zayo kunye nokuguquguquka, ibonelela ngamashishini ngomgangatho ophezulu kunye nezisombululo zemveliso ephezulu.

Isifundo

Intshayelelo:

I-Thermoforming yinkqubo yokwenza izinto ezininzi kwaye esebenzayo esetyenziswa kumashishini ahlukeneyo. Ukuqinisekisa imveliso engenamthungo kunye nomgangatho ophezulu, ukulungiswa kwezixhobo ezifanelekileyo, ukuphatha imathiriyeli ekrwada, kunye nokugcinwa kwazo kubalulekile.

ULungiselelo lweZixhobo:

Phambi kokuba uqalise imveliso, qinisekisa uqhagamshelo olomeleleyo kunye nobonelelo lwamandla kumatshini wakho we-2-station thermoforming. Ukuqhuba uhlolo olucokisekileyo lokufudumeza, ukupholisa, iinkqubo zoxinzelelo, kunye neminye imisebenzi ukuqinisekisa ukusebenza kwazo okuqhelekileyo. Faka ngokukhuselekileyo iimbumba ezifunekayo, uqinisekise ukuba zihambelana ngokugqibeleleyo ukukhusela nayiphi na impazamo enokwenzeka ngexesha lenkqubo yokuvelisa.

ULungiselelo lweMathiriyeli ekrwada:

Qala ngokukhetha iphepha leplastiki elifanelekileyo lokubumba, uqinisekise ukuba lihambelana neemfuno ezithile zeprojekthi. Nika ingqwalasela enkulu kubungakanani kunye nobukhulu, njengoko ezi zinto zinempembelelo enkulu kwintembeko yemveliso yokugqibela. Ngephepha leplastiki elilungiselelwe kakuhle, ubeka isiseko seziphumo ezingenasiphako ze-thermoforming.

Iisetingi Zobushushu:

Vula iphaneli yokulawula yomatshini wakho we-thermoforming kwaye usete ubushushu bokufudumala kunye nexesha. Cinga iimpawu zezinto zeplastiki kunye neemfuno zokubumba xa usenza olu hlengahlengiso. Vumela umatshini we-thermoforming ixesha elaneleyo lokufikelela kwiqondo lobushushu elibekiweyo, uqinisekisa ukuba iphepha leplastiki lifumana ukuthamba okufunwayo kunye nokubumba ukubunjwa okufanelekileyo.

Ukubumba - Ukupakisha :

Beka ngononophelo iphepha leplastiki elifudumeziweyo kwindawo yokungunda, uqinisekise ukuba lithe tyaba kwaye ligudile. Qalisa inkqubo yokubumba, uxhobisa isikhunta ukuba sisebenzise uxinzelelo kunye nobushushu ngaphakathi kwexesha elimiselweyo, ngobuchule ukubumba iphepha leplastiki kwifomu yalo oyifunayo. I-Post-forming, vumela iplastiki iqine kwaye ipholile ngokusebenzisa i-mold, iqhubela phambili kwi-stacking ecwangcisiweyo yocwangco ukuze i-palletizing esebenzayo.

Khupha iMveliso egqityiweyo:

Hlola ngokucokisekileyo imveliso nganye egqityiweyo ukuze uqiniseke ukuba iyahlangabezana nemilo efunekayo kwaye ithobela imigangatho ephezulu yomgangatho. Olu vavanyo lucokisekileyo luqinisekisa ukuba yindalo kuphela engenasiphako eshiya umgca wemveliso, iqinisa isidima sakho sokugqwesa.

Ukucoca kunye noLondolozo:

Ukugcina ukusebenza kakuhle kwezixhobo zakho ze-thermoforming, sebenzisa inkqubo yokucoca kunye nokugcinwa ngokucokisekileyo. Emva kokusetyenziswa, vula umatshini we-thermoforming kwaye uwukhuphe kumthombo wamandla. Ukucocwa ngokucokisekileyo kokungunda kunye nezixhobo zokuphelisa nayiphi na iplastiki eshiyekileyo okanye inkunkuma. Hlola rhoqo amacandelo ezixhobo ezahlukeneyo ukuqinisekisa ukusebenza kakuhle, ukukhusela imveliso engaphazamisekiyo.