RM-4 Isikhululo esine Thermoforming Machine

Iiparamitha zoomatshini

| ◆Imodeli: | RM-4 |

| ◆Max.Ingingqi yoLwakhiwo: | 820*620mm |

| ◆Max.Ukubumba ubude: | 100mm |

| ◆Ubukhulu.Ukutyeba kweShiti(mm): | 1.5 mm |

| ◆Uxinzelelo loMoya oluPhezulu(Ibha): | 6 |

| ◆Isantya soMjikelo owomileyo: | 61/cyl |

| ◆ Amandla okuqhwaba: | 80T |

| ◆Isixhobo sombane: | 380V |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Isinciphisi: | GNORD |

| ◆Isicelo: | iitreyi, izitya, iibhokisi, izivalo, njl. |

| ◆ Amacandelo angundoqo: | I-PLC, i-injini, i-Bearing, i-Gearbox, i-Motor, i-Gear, i-Pump |

| ◆Izixhobo ezifanelekileyo: | PP.PS.PET.CPET.OPS.PLA |

| Max.Ngundo Imilinganiselo | Amandla okuQhwatha | Isantya soMjikelo owomileyo | Max.Iphepha Ukutyeba | Max.Foming Ubude | Max.Umoya Uxinzelelo | Umbandela Ofanelekileyo |

| 820x620mm | 80T | 61/umjikelo | 1.5mm | 100mm | 6 Ibha | PP, PS, PET, CPET, OPS, PLA |

Ividiyo yeMveliso

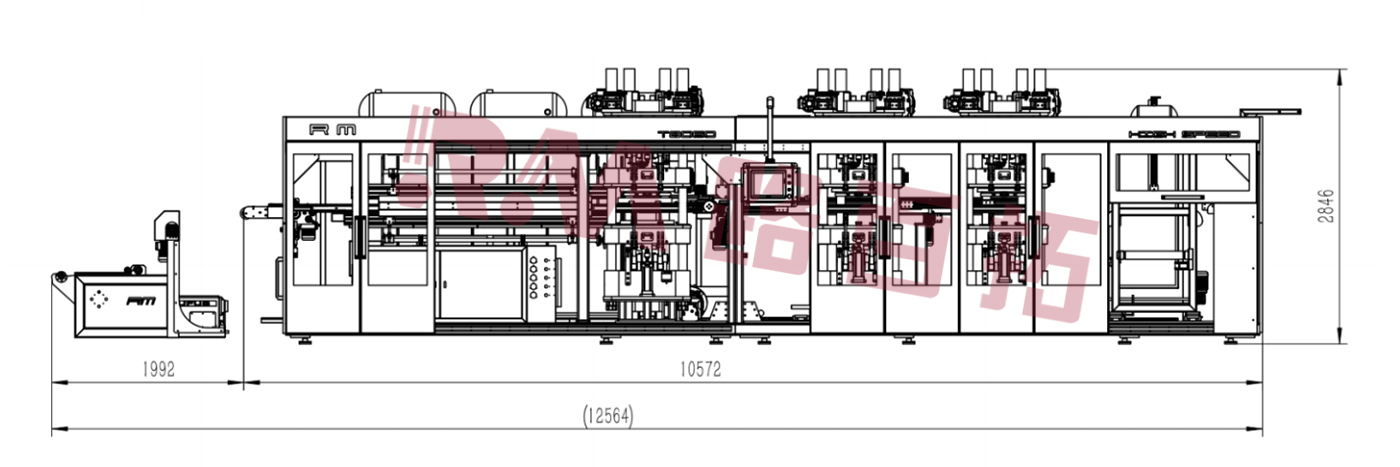

Umzobo wokuSebenza

Iimpawu eziphambili

✦ Ukulawulwa ngokuzenzekelayo: Isixhobo samkela inkqubo yokulawula ngokuzenzekelayo, enokulawula ngokuchanekileyo iiparitha ezifana nobushushu bokufudumala, ixesha lokubumba kunye noxinzelelo lokuqinisekisa ukuzinza kunye nokuhambelana kwenkqubo yokubumba.

✦ Utshintsho olukhawulezayo lwe-mold: Umatshini we-4-station thermoforming uxhotyiswe ngenkqubo yokutshintsha i-mold ekhawulezayo, eququzelela utshintsho olukhawulezayo lokubumba kunye nokulungelelanisa iimfuno zemveliso yeemveliso ezahlukeneyo, ngaloo ndlela iphucula ukuguquguquka kwemveliso.

✦ Ukonga amandla: Isixhobo samkela ubuchwepheshe obuphezulu bokugcina amandla, obunciphisa ngokufanelekileyo ukusetyenziswa kwamandla, ukunciphisa iindleko zemveliso, kunye nokusingqongileyo kwangaxeshanye.

✦ Kulula ukusebenza: Umatshini we-4-station thermoforming uxhotyiswe nge-interface yokusebenza enembile, ekulula ukuyisebenzisa kwaye kulula ukuyifunda, ukunciphisa iindleko zokuqeqeshwa kwabasebenzi kunye namazinga eempazamo zokuvelisa.

Indawo yesicelo

Umatshini we-4-station thermoforming usetyenziswa ngokubanzi kwishishini lokupakisha ukutya, kwaye ufanelekile ngakumbi kumashishini avelisa iimveliso zeplastiki ngomlinganiselo omkhulu ngenxa yokusebenza kwayo okuphezulu, umthamo ophezulu kunye nokuguquguquka.

Isifundo

Ukulungiswa kwezixhobo:

a.Qinisekisa ukuba umatshini we-4-station thermoforming uqhagamshelwe ngokukhuselekileyo kwaye uvuliwe.

b.Khangela ukuba inkqubo yokufudumeza, inkqubo yokupholisa, inkqubo yoxinzelelo kunye neminye imisebenzi eqhelekileyo.

c.Faka iimbumba ezifunekayo kwaye uqinisekise ukuba iimbumba zifakwe ngokukhuselekileyo.

Ukulungiselela imathiriyeli ekrwada:

a.Lungiselela iphepha leplastiki (iphepha leplastiki) elilungele ukubumba.

b.Qinisekisa ukuba ubukhulu kunye nobukhulu bephepha leplastiki liyahlangabezana neemfuno zokungunda.

Iisetingi zobushushu:

a.Vula iphaneli yokulawula umatshini we-thermoforming kwaye usethe ubushushu bokufudumala kunye nexesha.Yenza useto olufanelekileyo ngokwezinto zeplastiki ezisetyenzisiweyo kunye neemfuno zokungunda.

b.Lindela umatshini we-thermoforming ukuba ufudumale ukuya kwiqondo lobushushu elibekiweyo ukuqinisekisa ukuba iphepha leplastiki liyathambile kwaye liyabunjwa.

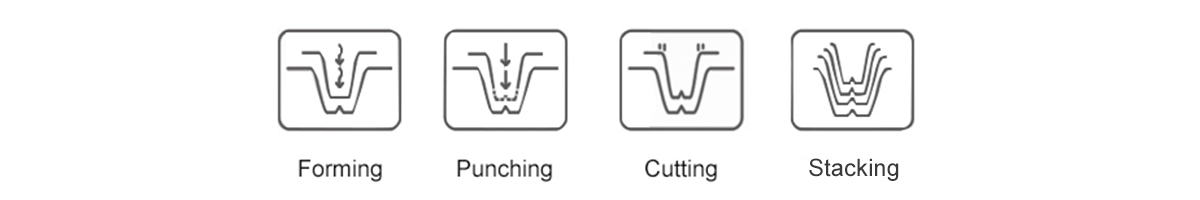

Ukubumba - ukugqobhoza emngxunyeni - ukugqobhoza komphetho - ukupakisha kunye nokupakisha:

a.Beka iphepha leplastiki elitshisayo kwi-mold kwaye uqinisekise ukuba lithe tyaba kwindawo yokubumba.

b.Qala inkqubo yokubumba, vumela isikhunta sisebenzise uxinzelelo kunye nobushushu ngaphakathi kwexesha elimiselweyo, ukwenzela ukuba iphepha leplastiki licinezele kwimo efunwayo.

c.Emva kokwenza, iplastiki eyenziweyo iyaqiniswa kwaye ipholile ngokubumba, kwaye ithunyelwe kwi-punching, i-edge punching kunye ne-palletizing ngokulandelelana.

Thatha imveliso egqityiweyo:

a.Imveliso egqityiweyo iyahlolwa ukuqinisekisa ukuba imilo kunye nomgangatho njengoko kufuneka.

Ukucoca kunye noLondolozo:

a.Emva kokusetyenziswa, cima umatshini we-thermoforming kwaye uwukhuphe kumthombo wamandla.

b.Coca iimbumba kunye nezixhobo zokuqinisekisa ukuba akukho ntsalela yeplastiki okanye enye inkunkuma.

c.Jonga rhoqo iindawo ezahlukeneyo zesixhobo ukuze uqinisekise ukuba isixhobo sikwimeko entle yokusebenza.