Wamkelekile ukubonisana kunye nothethathethwano

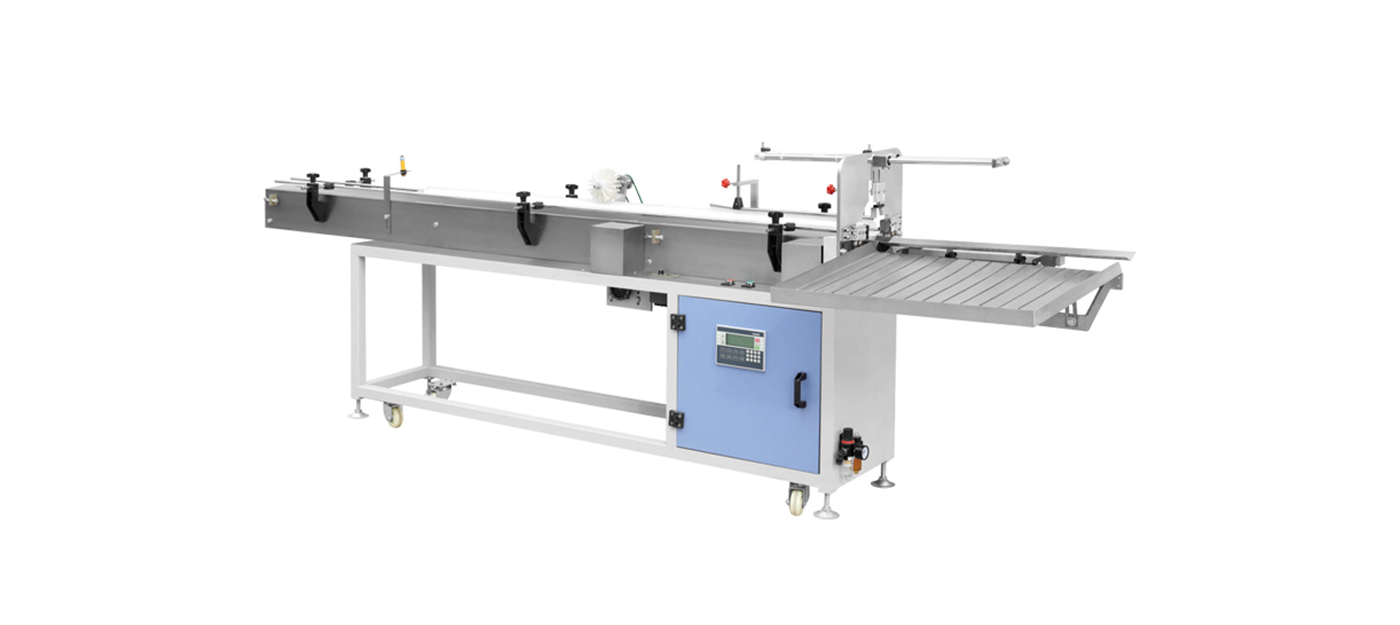

RM-4 Isikhululo esine Thermoforming Machine

Inkcazo

I-4-isikhululo esilungileyo kunye noxinzelelo olubi lomatshini we-thermoforming sisixhobo sokuvelisa esisebenzayo esinokusetyenziselwa ukuvelisa iibhokisi zeziqhamo zeplastiki ezilahlwayo, iimbiza zeentyatyambo, izivalo zekomityi yekofu kunye neziciko ezihonjisiweyo ezinemingxuma, njl. Esi sixhobo samkela itekhnoloji ye-thermoforming yoxinzelelo elungileyo kunye nengalunganga ukusetyenzwa kwephepha leplastiki kwimilo efunekayo, ubungakanani kunye noyilo oluhambelanayo lokubetha ngokufudumeza iphepha leplastiki kunye nokucinezela igesi yoxinzelelo elungileyo kunye nembi. Esi sixhobo sineeseti ezine zeendawo zokusebenzela ukwenza, ukugqobhoza umngxuma, ukugqobhoza komphetho, kunye nokupakishwa kunye ne-palletizing, ezinokuhlangabezana neemfuno zamashishini ahlukeneyo kunye nokuqinisekisa umgangatho kunye nokuhambelana kweemveliso.

Iiparamitha zoomatshini

| Indawo yokubumba | Amandla okubamba | Isantya sokubaleka | Ubukhulu bephepha | Ukubumba ukuphakama | Ukwenza uxinzelelo | Izinto eziphathekayo |

| Max. Ukungunda Imilinganiselo | Amandla okuQhwatha | Isantya soMjikelo owomileyo | Max. Iphepha Ukutyeba | Max.Foming Ubude | Max.Umoya Uxinzelelo | Umbandela Ofanelekileyo |

| 820x620mm | 80T | 61/umjikelo | 1.5mm | 100mm | 6 Ibha | PP, PS, PET, CPET, OPS, PLA |

Iimbonakalo

Ulawulo oluzenzekelayo

Isixhobo samkela inkqubo yolawulo oluzenzekelayo oluhamba phambili, olunokulawula ngokuchanekileyo iiparitha ezifana nobushushu bokufudumala, ixesha lokubumba kunye noxinzelelo lokuqinisekisa ukuzinza kunye nokuhambelana kwenkqubo yokubumba.

Utshintsho lokungunda olukhawulezayo

Umatshini we-4-station thermoforming uxhotywe ngenkqubo yokutshintsha i-mold ekhawulezayo, eququzelela utshintsho olukhawulezayo lokubumba kunye nokulungelelanisa iimfuno zemveliso yeemveliso ezahlukeneyo, ngaloo ndlela kuphuculwe ukuguquguquka kwemveliso.

Ukonga amandla

Isixhobo samkela iteknoloji ephucukileyo yokonga amandla, enciphisa ngokufanelekileyo ukusetyenziswa kwamandla, ukunciphisa iindleko zemveliso, kwaye ihambelana nokusingqongileyo kwangaxeshanye.

Kulula ukusebenza

Umatshini we-4-station thermoforming uxhotyiswe nge-interface yokusebenza enembile, ekulula ukuyisebenzisa kwaye kulula ukuyifunda, ukunciphisa iindleko zoqeqesho lwabasebenzi kunye namazinga eempazamo zokuvelisa.

Isicelo

Umatshini we-4-station thermoforming usetyenziswa ngokubanzi kwishishini lokupakisha ukutya, kwaye ufanelekile ngakumbi kumashishini avelisa iimveliso zeplastiki ngomlinganiselo omkhulu ngenxa yokusebenza kwayo okuphezulu, umthamo ophezulu kunye nokuguquguquka.

Isifundo