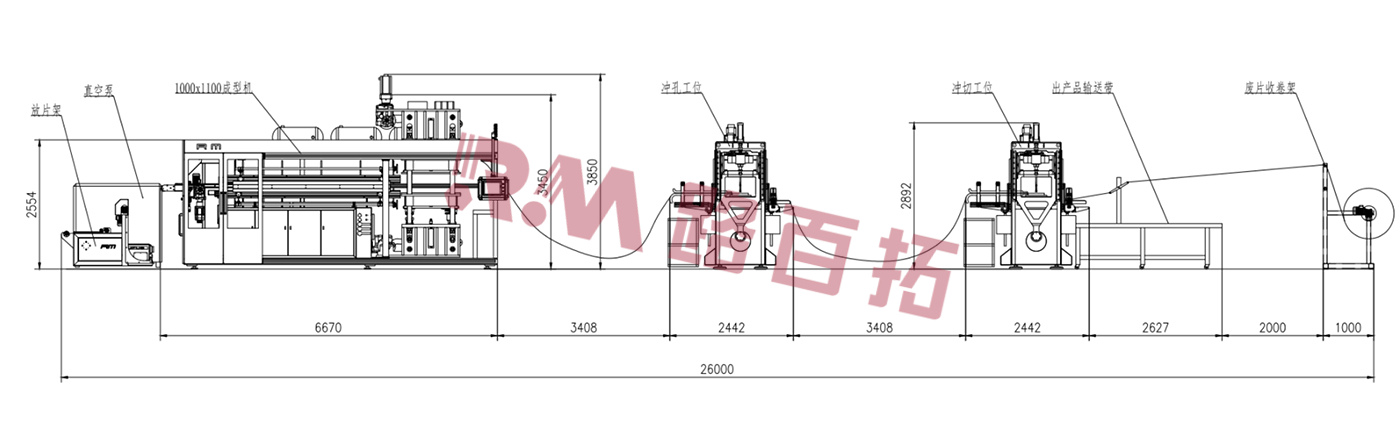

RM-T1011 + GC-7 + GK-7 Thermoforming Machine

Iiparamitha zoomatshini

| ◆Imodeli: | RM-T1011 |

| ◆ Ubuninzi. ubungakanani bokubumba: | 1100mm×1170mm |

| ◆ Ubuninzi. indawo yokwenza: | 1000mm×1100mm |

| ◆Umz. Indawo yokwenza: | 560mm×600mm |

| ◆ Ubuninzi. isantya sesantya semveliso: | ≤25Amaxesha/umzuzu |

| ◆Max.Ukubumba ubude: | 150mm |

| ◆ Ububanzi beshiti(mm): | 560mm-1200mm |

| ◆ Umgama ohambayo wokungunda: | Ukubetha≤220mm |

| ◆ Ubuninzi. amandla okubamba: | ukwenza-50T, i-punching-7T kunye nokusika-7T |

| ◆Ubonelelo lombane: | 300KW(amandla okufudumeza)+100KW(amandla okusebenza)=400kw |

| ◆Kuquka umatshini wokungqinga 20kw, umatshini wokusika 30kw | |

| ◆ Iinkcukacha zobonelelo lombane: | AC380v50Hz,4P(100mm2)+1PE(35mm2) |

| ◆Isixokelelwano seengcingo ezintlanu ezineentambo ezintlanu | |

| ◆PLC: | KEYENCE |

| ◆Servo Motor: | Yaskawa |

| ◆ Isinciphisi: | GNORD |

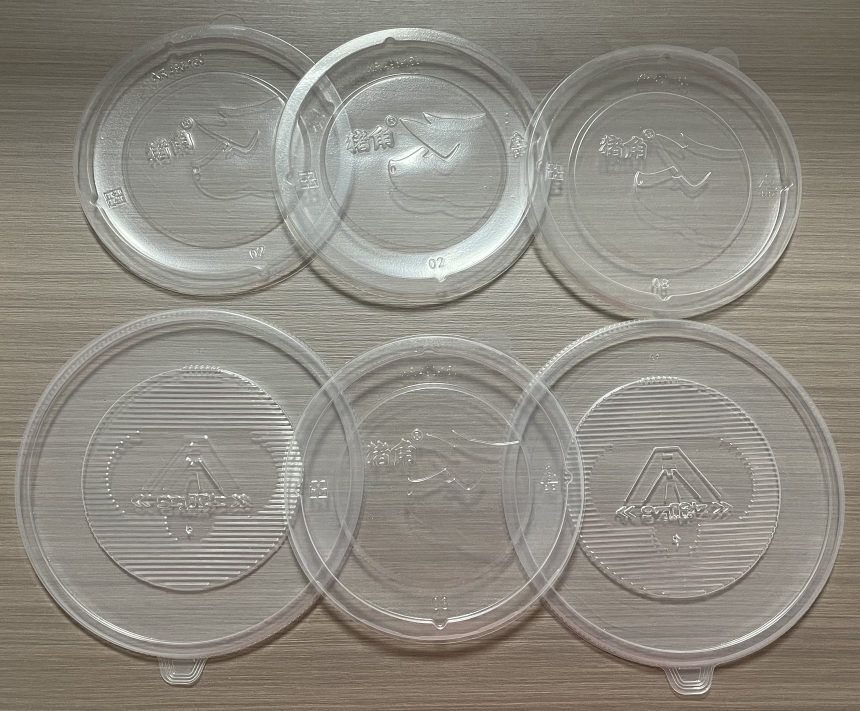

| ◆Isicelo: | iitreyi, izitya, iibhokisi, izivalo, njl. |

| ◆ Amacandelo angundoqo: | I-PLC, i-injini, i-Bearing, i-Gearbox, i-Motor, i-Gear, i-Pump |

| ◆Izinto ezifanelekileyo: | PP.PS.PET.CPET.OPS.PLA |

| Max. Imilinganiselo yokungunda | Amandla okuQhwatha | Ukugqobhoza Umthamo | Ukusika Umthamo | Max. Ukwenza Ubude | Max. Umoya Uxinzelelo | Isantya soMjikelo owomileyo | Max. Ukubetha/ Ukusika imilinganiselo | Max. Ukubetha/ Ukusika isantya | Umbandela Ofanelekileyo |

| 1000*1100mm | 50T | 7T | 7T | 150mm | 6 Ibha | 35r/min | 1000*320 | 100 sppm | PP, HI PS, PET, PS, PLA |

Ividiyo yeMveliso

Umzobo wokuSebenza

Iimpawu eziphambili

✦ Ukuveliswa ngokufanelekileyo: Umatshini omkhulu we-thermoforming wefomathi uthatha indlela yokusebenza yomgca wokuvelisa oqhubekayo, onokuthi ngokuqhubekayo kwaye ugqibezele ngokufanelekileyo inkqubo yokubumba imveliso. Ngokusebenzisa inkqubo yokulawula ngokuzenzekelayo kunye nokusebenza komatshini okhawulezayo, ukusebenza kakuhle kwemveliso kunokuphuculwa kakhulu ukuhlangabezana neemfuno zemveliso yobuninzi.

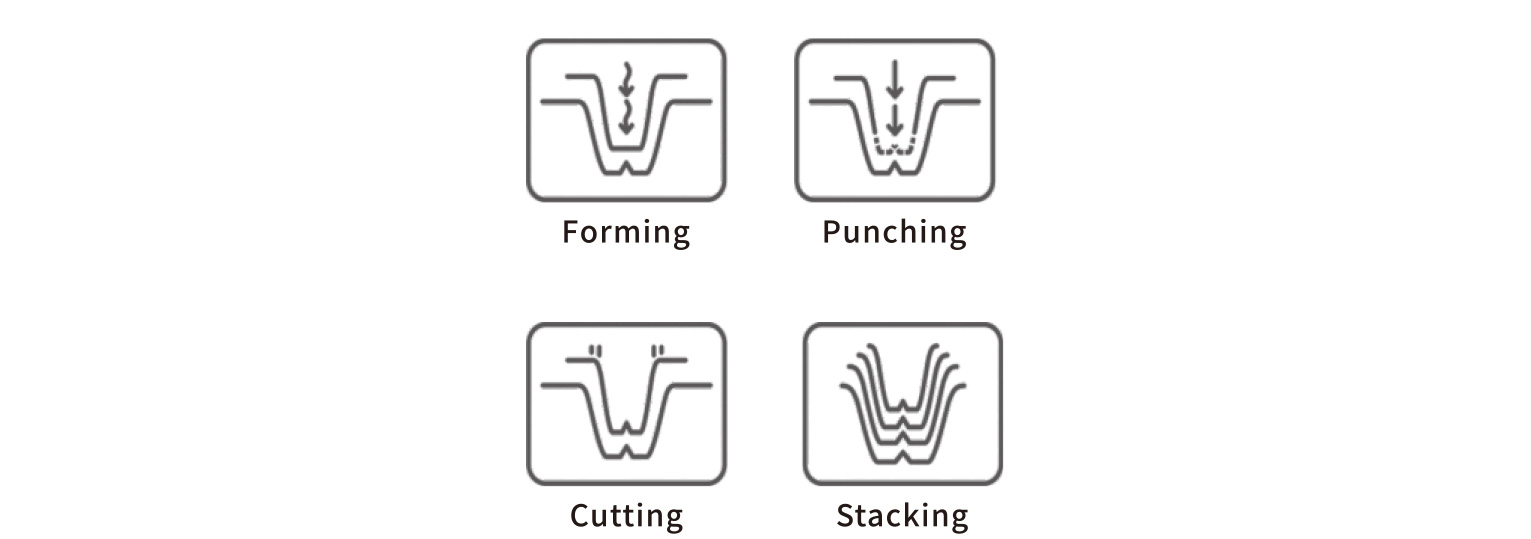

✦ Ukusebenza kwemisebenzi emininzi: umatshini unemisebenzi emininzi efana nokubumba, ukubethelwa, ukubethelwa komphetho kunye ne-palletizing.

✦ Ukubumba okuchanekileyo kunye neemveliso ezisemgangathweni ophezulu: Umatshini we-thermoforming yefomathi enkulu wamkela iteknoloji yokubumba ephucukileyo, enokulawula ngokuchanekileyo ubushushu bokufudumala, uxinzelelo kunye nexesha lokufudumeza ukuqinisekisa ukuba izinto zeplastiki zinyibilike ngokupheleleyo kwaye zisasazwe ngokulinganayo kwi-mold, ngaloo ndlela zenza iimveliso ezinomgangatho ophezulu womphezulu kunye nokuchaneka komda.

✦ Ukusebenza ngokuzenzekelayo kunye nokulawula okuhlakaniphile: Umatshini uxhotyiswe ngenkqubo yokusebenza ezenzekelayo, ekwazi ukuqonda imisebenzi efana nokutya okuzenzekelayo, ukuzenzela, ukubethelwa ngokuzenzekelayo, ukubethelwa komphetho ngokuzenzekelayo kunye ne-automatic palletizing. Umsebenzi ulula kwaye ulungele, ukunciphisa ukungenelela ngesandla, ukuphucula kakhulu ukusebenza kwemveliso kunye nokunciphisa iindleko zokuvelisa.

✦ Ukhuseleko kunye nokukhuselwa kwendalo: Umatshini omkhulu we-thermoforming yefomathi yenziwe ngezinto eziphezulu, ezinokuqina okuhle kunye nokuzinza. Ikwaxhotyiswe ngenkqubo yokukhusela ukhuseleko ukuqinisekisa ukhuseleko lwabaqhubi. Ngelo xesha, umatshini unoyilo lokulondoloza amandla, olunokunciphisa ukusetyenziswa kwamandla kunye nokunciphisa impembelelo kwindalo.

Indawo yesicelo

Ifomati enkulu yomatshini wokushisa i-RM-T1011 umatshini we-thermoforming isetyenziswa ngokubanzi kwishishini lokutya, ishishini lokupakisha ukutya kunye neshishini lempahla yasekhaya. Ngenxa yokusebenza kwayo okuphezulu, imisebenzi emininzi kunye neempawu ezichanekileyo, inokuhlangabezana neemfuno zemveliso yamashishini ahlukeneyo kwiimveliso zeplastiki kunye nokubonelela ngenkxaso eqinile kumashishini ukuphucula ukusebenza kwemveliso kunye nomgangatho wemveliso.

Isifundo

ULungiselelo lweZixhobo:

Ukuqalisa umatshini wakho we-thermoforming, khusela ifomati enkulu ethembekileyo yomatshini we-thermoforming RM-T1011 ngokuqinisekisa uqhagamshelwano lwawo olukhuselekileyo kunye nokuwuvula. Ukuhlolwa okubanzi kokufudumeza, ukupholisa, kunye neenkqubo zoxinzelelo kubalulekile ukuqinisekisa ukusebenza kwazo okuqhelekileyo. Khusela inkqubo yakho yokuvelisa ngokufaka ngobunono iimolds ezifunekayo, uqinisekise ukuba zimiliselwe ngokuqinileyo ukuze zisebenze kakuhle.

ULungiselelo lweMathiriyeli ekrwada:

Ukufezekisa imfezeko kwi-thermoforming kuqala ngokulungiselela ngokucokisekileyo izinto ezikrwada. Khetha ngononophelo iphepha leplastiki elilungele ukubumba, kwaye uqinisekise ubungakanani bayo kunye nobukhulu bayo buhambelana neemfuno ezithile zokubumba. Ngokunikela ingqalelo kwezi nkcukacha, ubeka inqanaba leemveliso ezigqibeleleyo zokuphela.

Iisetingi Zobushushu:

Vula amandla okwenyani enkqubo yakho ye-thermoforming ngokuqwalasela ngobuchule ubushushu bokufudumala kunye nexesha ngephaneli yokulawula. Lungisa useto lwakho ukuze luhambelane nemathiriyeli yeplastiki kunye neemfuno zokungunda, ukufezekisa iziphumo ezilungileyo.

Ukubumba-Ukugqobhoza komngxunya-Ukubetha umphetho-Ukupakisha kunye nokuPaleti:

Beka ngobunono iphepha leplastiki elifudumeziweyo kwindawo yokubumba, uqinisekise ukuba ihambelana ngokugqibeleleyo kwaye ikhululekile kuyo nayiphi na imibimbi okanye ukuphazamiseka okunokuthi kuphazamise inkqubo yokubumba.

Qalisa inkqubo yokubumba, usebenzise ngononophelo uxinzelelo kunye nobushushu ngaphakathi kwexesha elichaziweyo lokubumba iphepha leplastiki ngokuchanekileyo kwifom efunwayo.

Nje ukuba ukubunjwa kugqityiwe, imveliso yeplastiki esandula ukumila iyekwe ukuba yomelele kwaye iphole ngaphakathi kokungunda, ngaphambi kokuba iqhubele phambili ekugqobhozeni komngxuma, ukugqobhoza komphetho, kunye nokupakishwa ngocwangco ukuze kufakwe ipali.

Khupha iMveliso egqityiweyo:

Hlola imveliso nganye egqityiweyo ngocoselelo ukuqinisekisa ukuba iyahambelana nemilo efunekayo kwaye ithobela imigangatho yomgangatho osekiweyo, wenze naluphi na uhlengahlengiso oluyimfuneko njengoko lufuneka.

Ukucoca kunye noLondolozo:

Ekugqityweni kwenkqubo yokuvelisa, amandla phantsi umatshini we-thermoforming kwaye uwukhuphe kumthombo wamandla ukuze ulondoloze amandla kunye nokugcina ukhuseleko.

Ukucoca ngokucokisekileyo imibumba kunye nezixhobo ukuphelisa nayiphi na iplastiki eshiyekileyo okanye inkunkuma, ukugcina ixesha elide lokubumba kunye nokuthintela iziphene ezinokuthi zibekho kwiimveliso ezizayo.

Sebenzisa ishedyuli yokulungisa rhoqo ukuhlola kunye nenkonzo yezixhobo ezahlukeneyo zezixhobo, uqinisekisa ukuba umatshini we-thermoforming uhlala ukwimeko efanelekileyo yokusebenza, ukukhuthaza ukusebenza kakuhle kunye nokuphila ixesha elide kwimveliso eqhubekayo.